MARKETS

AEROSPACE

Lightweight design is an extensively explored and utilized concept in many industries, especially in aerospace applications. The principle of lightweight design is to use less material with lower density while ensuring the same or enhanced technical performance. A typical approach to achieve lightweight design for aerospace components is to apply advanced lightweight materials or composites to replace metal components. Metals have the advantages of ease of manufacture, but composite materials are particularly attractive to aviation and aerospace applications because of their exceptional strength- and stiffness-to-density ratios and superior physical properties.

Composite manufacturing processes, such as vacuum bagging, require high temperatures for chemical reactions which result in sticky situations. We offer the perfect processing solutions for your composite manufacture with our extensive line of chemically inert, anti-adherent and high temperature processing aids.

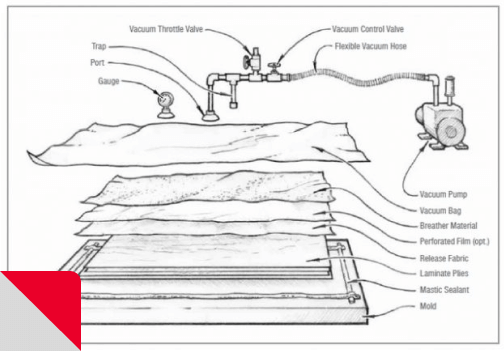

Vacuum Bagging

Vacuum bagging is a manufacturing process that makes composite parts with the use of a mold with the form of the part and with the use of several layers that create mechanical pressure on the laminate during its cure cycle. These molds can be brought into an autoclave oven where the parts cure under the pressure. Flexible release films, fabrics and tapes are part of the layers that allow the part to release from the mold upon cure, while applying the pressure during the cure. HiTemp line of fluoropolymer films, fabrics and tapes, withstand the temperatures, and have the chemical inertness and release properties required for the process.