APPLICATIONS

Belting products

HITEMP fabricates custom designed belts to meet application specific requirements for precision and durability. Belting products typically consist of a glass, kevlar or nomex substrate coated with PTFE or silicone rubber.

Exceptional non-stick properties is the principal benefit of HiTemp belting products. Other characteristics include flexibility, dimensional stability, thermal and chemical resistance, and ability to impart a texture or smooth finish. Belts are designed with high tensile strength, dimensional stability, flex fatigue resistance, and crafted for durability. Applications for HITEMP belting products include, but are not limited to:

- Conveyor belts for tortilla and other flat bread products

- Conveyor belts for poultry and meat processing

- Fuse pressing belts

- Beverage Cans belting

- Belts for carpet and flooring manufacturers

- Textile and screen printing belts

- Drying and curing oven belts

- Belts for shrink wrap tunnels

- Paper converting vertical side sealer belts

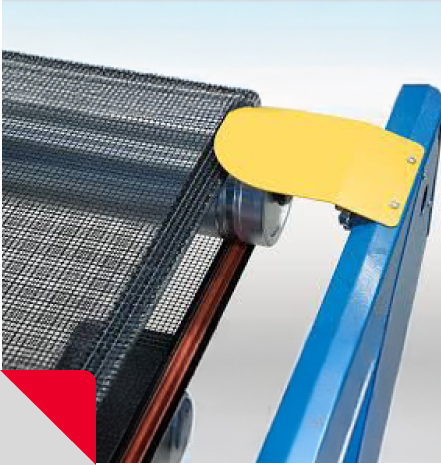

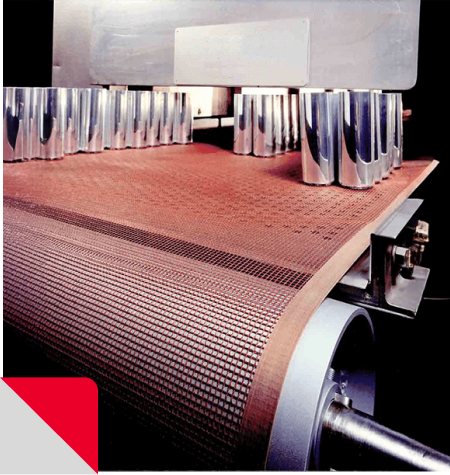

Beverage Cans

High-temperature oven belts are used in industries like food processing, packaging, textile, screen printing, composites, fuse pressing, flooring, solar panels, circuit boards, and any application requiring continuous material transport through a high-temperature environment.

These conveyors face extreme conditions with elevated temperatures, chemical exposure, moist liquid environments, UV radiation, elevated tensions and pressures, corrosion and abrasion to name a few. HiTemp designs and formulates our open mesh and solid belts to last offering thermal, release, dimensional stability and abrasion resistance under extreme conditions. Our PTFE and silicone belting are inert, wear resistant, non-flammable, with high-tensile.

HiTemp application specialists can conduct on-site evaluations and offer a durable belting solution while assessing and troubleshooting your ovens.

Dryer conveyors

High-temperature oven belts are used in industries like food processing, packaging, textile, screen printing, composites, fuse pressing, flooring, solar panels, circuit boards, and any application requiring continuous material transport through a high-temperature environment.

These conveyors face extreme conditions with elevated temperatures, chemical exposure, moist liquid environments, UV radiation, elevated tensions and pressures, corrosion and abrasion to name a few.

HiTemp designs and formulates our open mesh and solid belts to last offering thermal, release, dimensional stability and abrasion resistance under extreme conditions. Our PTFE and silicone belting are inert, wear resistant, non-flammable, with high-tensile. HiTemp application specialists can conduct on-site evaluations and offer a durable belting solution while assessing and troubleshooting your ovens.

• HiTef Food Grade T 10 Red, 33 x 36 yards

• HiTef Food Grade T 10 Red, 52

• HiTef Food Grade T 10 Red

• HiTef Food Grade T 10 Teja, 33

• HiTef Food Grade T 10 Teja, 44

• HiTef Food Grade T 10 Teja, 52

• HiTef Food Grade T 10 Teja

• HiTef Premium Food Grade T 10 Blue, 34

• HiTef Premium Food Grade T 10 Copper, 34

Flat Bread

A flatbread is made with water, flour, and salt and exists in various cultures throughout the world. The thickness of the bread can range from a few millimeters to a few centimeters. Multigrain variants of flatbread are gaining popularity owing to increased health awareness. Moreover, factors such as pH, water activity, and moisture content affect the quality of flatbread products. Whether processing tortilla, pizza, pita, naan or any flat bread, equipment manufacturers continue to design machinery to process the fast increasing flat bread market which is expected to double by 2026 worldwide. HiTemp provides the most extensive line of engineered belts and release liners for your equipment. From abrasion resistance, to heat transfer, to lasting release, give us a call.

HiTemp Materials Corp offers leadership in tortilla belt innovation. We have developed the most varied line of dip-coats and laminates, and fabricate PTFE belts with precision to last in your flour tortilla lines such as;

• LAWRENCE EQUIPMENT

• JC FORD EQUIPMENT

• KV SYSTEMS

• CASA HERRERA

• AM MANUFACTURING

Related Products

• HiLam Food Grade Prem 10 Auburn

• HiTef Food Grade Prem 10 Azulejo

• HiTef Food Grade Prem 10 Copper-Red

• HiTef Food Grade Prem 10 Copper

• HiTef Food Grade Premium T 10 Azulejo, 34

• HiTef Food Grade Premium T 10 Azulejo, 55

• HiTef Food Grade T 10 Blue

• HiTef Food Grade T 10 Natural, 33 x 36 yards

• HiTef Food Grade T 10 Natural

Meat Searing & Grilling

Further processing of meats requires cooking, searing, roasting, or any process that will apply heat to the product. Whether you are fully cooking, pre-cooking or just searing, equipment manufacturers continue to design machinery to process the highly demanding environment requiring increasing outputs, high heat, ability to withstand moist and abrasive additives, while releasing. HiTemp provides the most extensive line of engineered belts, release liners and tapes for your equipment. We also provide the ancillary equipment like heat sealers, insulating bottom boards and patches required for your belts and liners. HiTemp application specialists can conduct on-site evaluations and offer a durable material solution while assessing and troubleshooting your equipment. From abrasion resistance, to heat transfer, to lasting release, give us a call.

Related Products

• HiTemp HiTef Food Grade T 10 Red Copper-Red

• HiTef Food Grade Premium 12 Black, 1200mm x 18510mm

• HiTef Food Grade Premium 12 Black, 1200mm x 20390mm

• HiTef Food Grade Premium 12 Black

• HiTef Food Grade Premium 14 Black

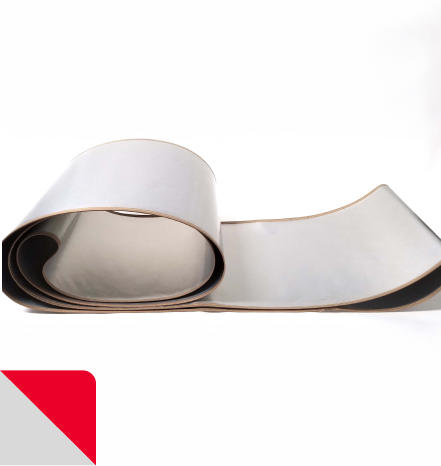

Paper Converting/Wrapping

HiTemp Materials offers a full range of vertical side sealer belts that provide superior performance in a variety of covering and wrapping applications.

Rubber backed Carpets

Rubber backing is typically applied to the carpet using heat to vulcanize the rubber and bond the carpet fibers. Various chemicals, adhesives, solvents and vulcanizing agents are used in the process. Rubber-backed carpet manufacturing operates under high mechanical stress and pressures to ensure proper bonding.

HiTemp offers the most diverse line of tough, chemically inert, and durable release belts, liners and tapes that operate at 550F continuously. Whether you are looking for a belt to go through an oven, or a press pad release liner, or a protective cover, we have the durable performance composite solution.

HiTemp application specialists can conduct on-site evaluations and offer a durable material solution while assessing and troubleshooting your ovens.

Screen Printing

Screen printing curing ovens in the graphic arts industry are essential for the proper drying and curing of inks on various substrates including card, paper, board, metal and textiles.

HiTemp designs and formulates our open mesh and solid belts to last offering thermal, release, dimensional stability and abrasion resistance under extreme conditions.

Textile drying

Processing textiles can require elevated temperatures for drying, heat-setting, curing, dying, bonding, printing and finishing. PTFE conveyors are ideally suited for transporting textiles during these processes as they provide a low friction non-stick surface at elevated temperature. They are inert to the dyes, chemicals and agents that are used in these processes. PTFE belts are light weight thus reducing energy consumption and dimensional stable for sustained tracking.

From wovens to non-wovens to knits or any textile, HiTemp provides the most diverse range of open mesh and solid impermeable belting substrates with super smooth or textured finishes.

HiTemp application specialists can conduct on-site evaluations and offer a durable belting solution while assessing and troubleshooting your ovens.