MARKETS

General Industrial

Industrial applications demand durable, high-performance, and flexible material solutions that can withstand rigorous environments while maintaining efficiency. For belting, materials must ensure resistance to corrosion, maintain integrity under high-pressure filling processes, and provide superior formability. Conveyor belting requires materials that deliver strength, flexibility, and wear resistance, suitable for handling high loads and continuous operation in various industries. In screen printing, robust and flexible materials are essential to achieve consistent, high-quality prints while withstanding repeated use. For textile drying, heat-resistant and breathable materials ensure optimal performance and longevity in high-temperature conditions. Together, these solutions support reliable, efficient, and long-lasting operations across diverse industrial sectors.

Beverage Cans

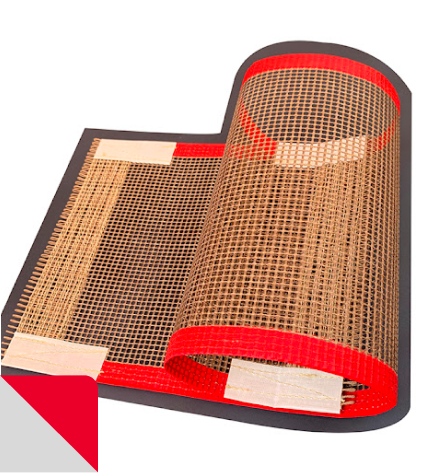

High-temperature oven belts are used in industries like food processing, packaging, textile, screen printing, composites, fuse pressing, flooring, solar panels, circuit boards, and any application requiring continuous material transport through a high-temperature environment.

These conveyors face extreme conditions with elevated temperatures, chemical exposure, moist liquid environments, UV radiation, elevated tensions and pressures, corrosion and abrasion to name a few. HiTemp designs and formulates our open mesh and solid belts to last offering thermal, release, dimensional stability and abrasion resistance under extreme conditions. Our PTFE and silicone belting are inert, wear resistant, non-flammable, with high-tensile.

HiTemp application specialists can conduct on-site evaluations and offer a durable belting solution while assessing and troubleshooting your ovens.

Conveyor Belting

High-temperature oven belts are used in industries like food processing, packaging, textile, screen printing, composites, fuse pressing, flooring, solar panels, circuit boards, and any application requiring continuous material transport through a high-temperature environment. These conveyors face extreme conditions with elevated temperatures, chemical exposure, moist liquid environments, UV radiation, elevated tensions and pressures, corrosion and abrasion to name a few.

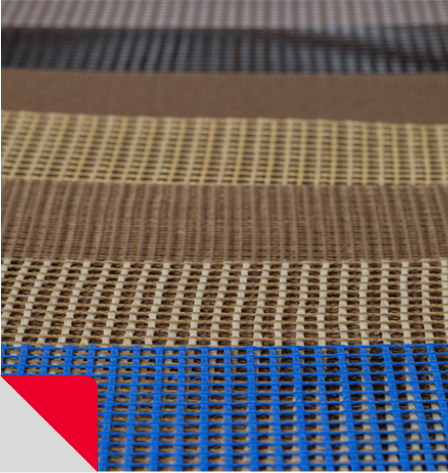

HiTemp designs and formulate our open mesh and solid belts to last offering thermal, release, dimensional stability and abrasion resistance under extreme conditions. Our PTFE and silicone belting are inert, wear resistant, non-flammable, with high-tensile.

HiTemp application specialists can conduct on-site evaluations and offer a durable belting solution while assessing and troubleshooting your ovens.

Screen Printing

Screen printing curing ovens in the graphic arts industry are essential for the proper drying and curing of inks on various substrates including card, paper, board, metal and textiles.

HiTemp designs and formulates our open mesh and solid belts to last offering thermal, release, dimensional stability and abrasion resistance under extreme conditions.

Textile drying

Processing textiles can require elevated temperatures for drying, heat-setting, curing, dying, bonding, printing and finishing. PTFE conveyors are ideally suited for transporting textiles during these processes as they provide a low friction non-stick surface at elevated temperature. They are inert to the dyes, chemicals and agents that are used in these processes. PTFE belts are light weight thus reducing energy consumption and dimensional stable for sustained tracking.

From wovens to non-wovens to knits or any textile, HiTemp provides the most diverse range of open mesh and solid impermeable belting substrates with super smooth or textured finishes.

HiTemp application specialists can conduct on-site evaluations and offer a durable belting solution while assessing and troubleshooting your ovens.