APPLICATIONS

Pressure sensitive adhesive tapes

HITEMP provides a tape product line for applications which require superior release or slip, dimensional and/or thermal stability and/or chemical resistance. The unique behavior of these engineered composites results in products that are more cost effective than conventional composites.

High Performance PTFE composite tapes are available with an acrylic or silicone pressure sensitive adhesive, are flexible and work in demanding applications where heat, corrosion, adherence/stick and friction are the norm.

Flat Bread

A flatbread is made with water, flour, and salt and exists in various cultures throughout the world. The thickness of the bread can range from a few millimeters to a few centimeters. Multigrain variants of flatbread are gaining popularity owing to increased health awareness. Moreover, factors such as pH, water activity, and moisture content affect the quality of flatbread products. Whether processing tortilla, pizza, pita, naan or any flat bread, equipment manufacturers continue to design machinery to process the fast increasing flat bread market which is expected to double by 2026 worldwide. HiTemp provides the most extensive line of engineered belts and release liners for your equipment. From abrasion resistance, to heat transfer, to lasting release, give us a call.

HiTemp Materials Corp offers leadership in tortilla belt innovation. We have developed the most varied line of dip-coats and laminates, and fabricate PTFE belts with precision to last in your flour tortilla lines such as;

• LAWRENCE EQUIPMENT

• JC FORD EQUIPMENT

• KV SYSTEMS

• CASA HERRERA

• AM MANUFACTURING

Heat Sealer Bars

HiTemp Materials offers a complete range of PTFE Adhesive Tapes to perform in a variety of heat seal packaging processes involving impulse heat sealers and hot bar sealers. HiTemp Materials provides a non-stick, abrasion resistant surface designed for use in high temperature heat sealing applications, including food, medical and pharmaceutical packaging. These highly durable tapes allow for increased process speeds and minimal down time increasing overall process efficiency. Different backings and adhesive systems are combined to offer a variety of solutions that balance cost and performance.

Meat Searing & Grilling

Further processing of meats requires cooking, searing, roasting, or any process that will apply heat to the product. Whether you are fully cooking, pre-cooking or just searing, equipment manufacturers continue to design machinery to process the highly demanding environment requiring increasing outputs, high heat, ability to withstand moist and abrasive additives, while releasing. HiTemp provides the most extensive line of engineered belts, release liners and tapes for your equipment. We also provide the ancillary equipment like heat sealers, insulating bottom boards and patches required for your belts and liners. HiTemp application specialists can conduct on-site evaluations and offer a durable material solution while assessing and troubleshooting your equipment. From abrasion resistance, to heat transfer, to lasting release, give us a call.

Polyethelyne Processing

Polyethylene is the plastic of choice in the packaging industry. It is inexpensive, highly chemically resistant, durable, abrasion resistant, water resistant and a good electrical insulator.

Polyethylene film blowing and/or sealing and cutting of bags, such as T-shirt lines, require a release fabric that will not tear under the extended and continuous pounding encountered by the plastic bag during the sealing process.

HiTemp has engineered PTFE coatings for durability and tear strength. Our films, fabrics and tapes will provide consistency and strength to your seals.

Related Products

Printed Circuit Boards/Electronics

Masking select parts of the printed circuit board is a necessary part of the manufacturing process in order to ensure connectors, test sites and pins are not coated, which could affect performance. We support gold finger plating, splash and fume protection, wave soldering, hot air leveling and conformal coating in electronics assembly with a variety of specialty adhesive tapes designed for electronics assembly. Offering specialty adhesive tapes with special formulations for softness, adhesives can create fine lines and conform to trace lay-downs, mitigating the chance of defects in the finished part resulting in less quality issues.

Screen Printing

Screen printing curing ovens in the graphic arts industry are essential for the proper drying and curing of inks on various substrates including card, paper, board, metal and textiles.

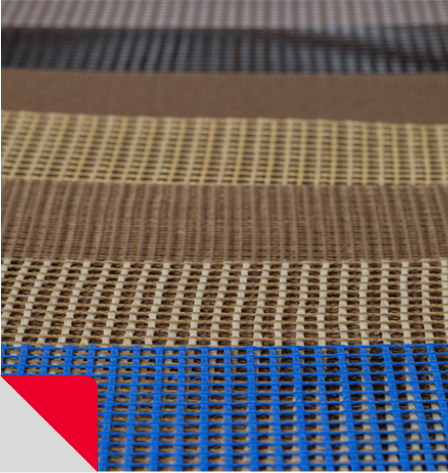

HiTemp designs and formulates our open mesh and solid belts to last offering thermal, release, dimensional stability and abrasion resistance under extreme conditions.

Vaccum Bagging

Vacuum bagging is a manufacturing process that makes composite parts with the use of a mold with the form of the part and with the use of several layers that create mechanical pressure on the laminate during its cure cycle. These molds can be brought into an autoclave oven where the parts cure under the pressure. Flexible release films, fabrics and tapes are part of the layers that allow the part to release from the mold upon cure, while applying the pressure during the cure. HiTemp line of fluoropolymer films, fabrics and tapes, withstand the temperatures, and have the chemical inertness and release properties required for the process.

Vinyl Windows

The manufacturing of PVC and plastic profiles often involves ‘welding’ two PVC frame sections together. This is accomplished by melting the two adjoining ends so that the melted plastic joins together and hardens in its welded state. The completed frames can be used to make windows, skylights, and some door profiles. Equipment used can be Protection of heat platen during corner weld process – PTFE glass tape or fabric is applied to weld plates to allow for heat to pass through the tape to accomplish a joint weld. The melted PVC will not adhere to the tape or fabric surface which allows for a clean weld. The equipment used for this process can vary in size and complexity.

The simplest equipment is referred to as a single point welder. This equipment allows the operator to weld one window corner at a time. It is typically used for custom window profiles, or by small companies with relatively low volumes of window production. The next style of equipment is semi-automated and is referred to as a two-point welder. As expected, this equipment allows the operator to weld two window corners at one time. The most popular style of equipment is used for high volume facilities – the equipment is referred to as a four-point welder. This equipment is usually more automated and allows for the sealing of a complete 4 corner window or door in one step. The moving image shows a hot plate which is covered with PTFE-glass tape on both sides. The angled edge of the PVC profile becomes molten against the platen. The platen is then automatically removed and the two molten ends are pushed together and held in place while the molten plastic is held in place, forming the corner of a PVC window frame.

Related Products