Flooring

Flooring

The flooring market is at the forefront of material science innovation. Modern man-made materials have rapidly evolved to replace earth favorites such as wood and stone. Demand for lightweight, easy to install, scratch resistant, flood resistant and modern stylish high-end chic designs have required engineered composite flooring. To process this innovative flooring, high temperatures and chemical reactions are the norm.

features-and-benefits

| Features | Benefits |

|---|---|

| Low Surface Energy | Excellent release and self-cleaning capabilities |

| Functional temperature range from -200°C (-328°F) to 165°C (330°F) | |

| Highest Dielectric Strength | Excellent insulator in many applications |

| Non-Flammable | Meets safety requirements for aviation and military applications |

| Highest mechanical strength in fluoropolymer film | Allows greater design flexibility over other fluoropolymers |

| Lower density than ETFE and FEP | Lighter weight constructions for high performance applications |

| Highest Abrasion resistance | Suitable for tough indoor and outdoor environments |

CHEMFILM® PFA-PG Fluoropolymer Film Typical Properties*

| Typical Properties | Test Method | Value | Units |

|---|---|---|---|

| General | |||

| Specific Gravity | ASTM D-792 | 1.68 | |

| Yield | 22(115) | m2/kg (ft2/lb) | |

| Water Absorption, 24 hr. | <0.01 | % | |

| Mechanical | |||

| Tensile Strength | ASTM D-882 | 55(8000) | MPa (psi) |

| Elongation, Ultimate | ASTM D-882 | 250 | % |

| Tensile Modulus | ASTM D-882 | 1375(200000) | MPa (psi) |

| Initial Tear Strength | ASTM D-1004 | 4.4(450) | N(gm/mil) |

| Propagation Tear Strength, 1 mil | ASTM D-1922 | 11.6(1200) | N(gm/mil) |

| Fold Endurance (M.I.T) | ASTM D-2176 | >250000 | cycles |

| Electrical | |||

| Dielectric Strength, 1 mil | ASTM D-149 | 216(5500) | kV/mm (V/mil) |

| Dielectric Constant, 1 kHz | ASTM D-150 | 2.55-2.63 | |

| Dissipation Factor, 1 kHz | ASTM D-150 | <0.005 | |

| Thermal | |||

| Melt Point | ASTM D-3418 | 240(465) | °C (°F) |

| Continuous Service Temperature | 300-340 | °C (°F) | |

| Flammability | ASTM UL-94 | V-0 | |

| Heat Sealing Temperature | 245-260(475-500) | °C (°F) | |

Related Documents

Application

- I. Release Press Liners/Covers

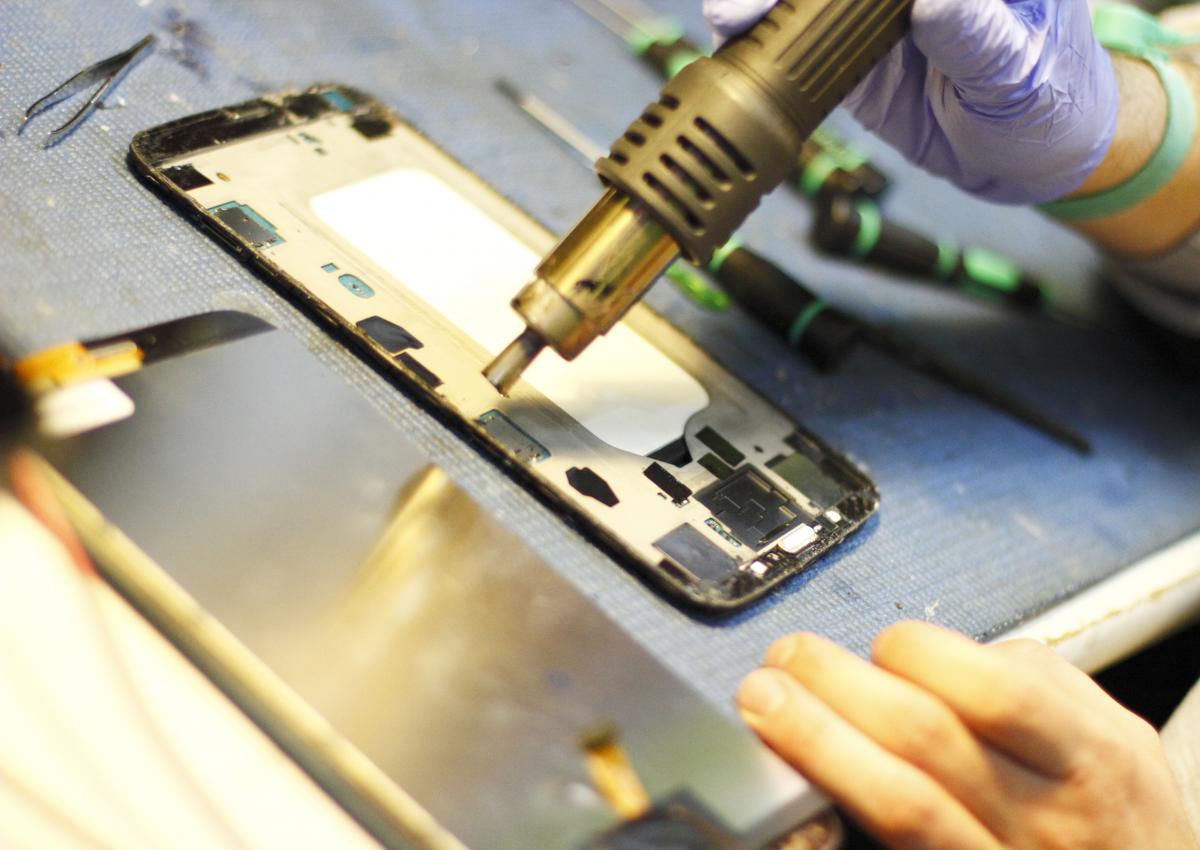

Processing materials from textiles, food, plastics, aerospace composites, chemicals, floors, and any product that require heat to be processed, may go through an oven. High temperature ovens typically will require conveyors or liners/covers that will withstand high temperature, chemical environments while offering release in direct product contact applications. HiTemp provides the most extensive line of engineered belts and release liners for your ovens. We also provide the ancillary equipment like heat sealers, insulating bottom boards and patches required for your belts and liners. HiTemp application specialists can conduct on-site evaluations and offer a durable material solution while assessing and troubleshooting your ovens. HiTemp offers the most diverse line of chemically inert, high temperature and release processing films, fabrics and tapes. Whether you are looking for a belt to go through an oven, or a press pad release liner, or a protective cover, we have the durable performance composite solution.

Related Products- HiTemp HiTef Elastomer Grade SB 16 DB M Belts

- HiTemp HiTef Elastomer Grade SB 20 DB M Belts

- HiTemp HiTef Elastomer Grade TB 27 B M Belts

- HiTemp HiTef Elastomer Grade SB 28 DB M Belts

- HiTemp HiTef Elastomer Grade TB 31 B M Belts

- HiTemp HiTef Elastomer Grade ST 35 DB M Belts

- HiTemp HiTef Elastomer Grade TB 41 B M1 Belts